Digitalization and intelligentization of production lines

With the solid promotion of the innovation and development strategy of industrial Internet, the construction of networks, platforms, security and other systems is constantly improving, and the integration and application of industrial Internet in intelligent manufacturing are becoming increasingly widespread. As an implementation path for intelligent manufacturing, digital platforms based on industrial internet are becoming increasingly important in production and manufacturing< Br/>

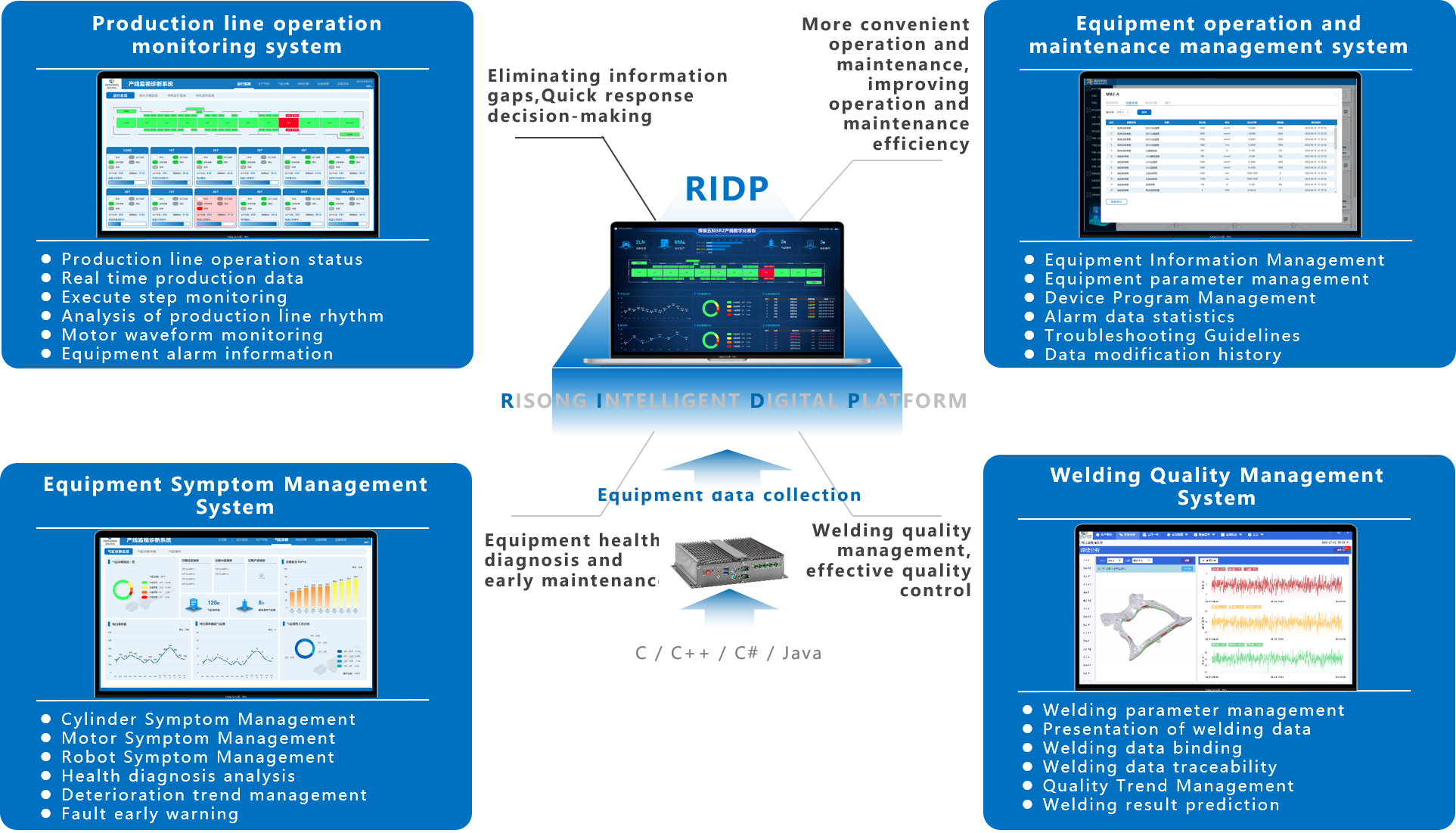

Based on more than ten years of manufacturing experience in the automotive industry and service experience from dozens of car companies, through independent research and continuous innovation, Risong Hokuto has innovatively developed and launched the Ruisong Intelligent Digital Platform RIDP (R: Ruisong, Intelligent: Intelligent, Digital: Digital, Platform: Platform) to meet the needs of industry development, which can effectively solve the pain points in the operation of manufacturing production lines.

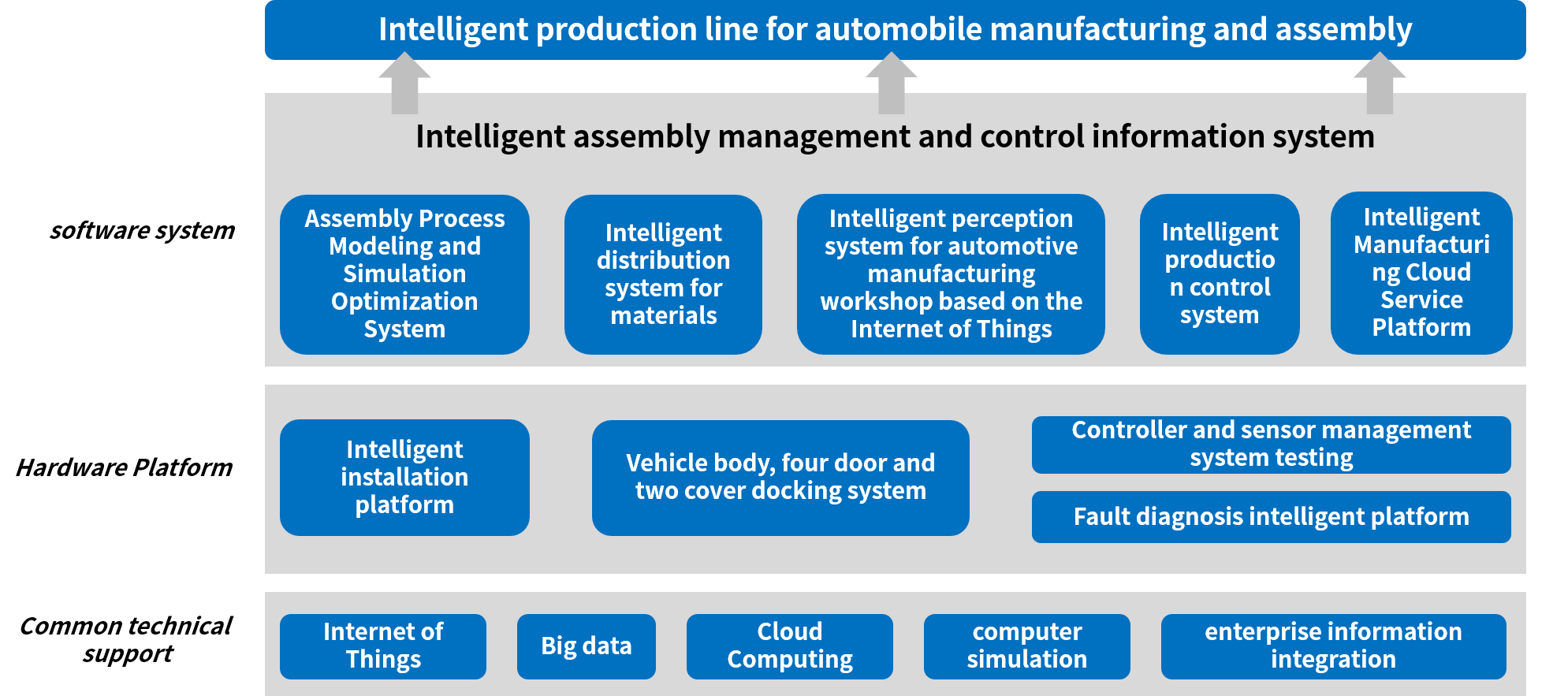

Integrated solution for intelligent assembly of automobiles

Risong Hokuto Automotive's intelligent assembly overall solution adopts high-tech automation solutions in all aspects - "intelligent visual guidance technology," "intelligent tightening technology," and "intelligent quality control technology." Multiple core technologies have reached the leading domestic and international levels. The independently developed machine vision intelligent assembly technology has the characteristics of large measurement range, good flexibility, and high accuracy, which can achieve high automation rate, high production efficiency, high production quality, and high flexibility in automatic assembly. The independent and controllable nature of flexible technology allows automobile manufacturers to easily adjust production rhythms, production models, etc., achieving high flexibility and customization, reducing production costs such as updating automobile manufacturing equipment and improving personnel skills.

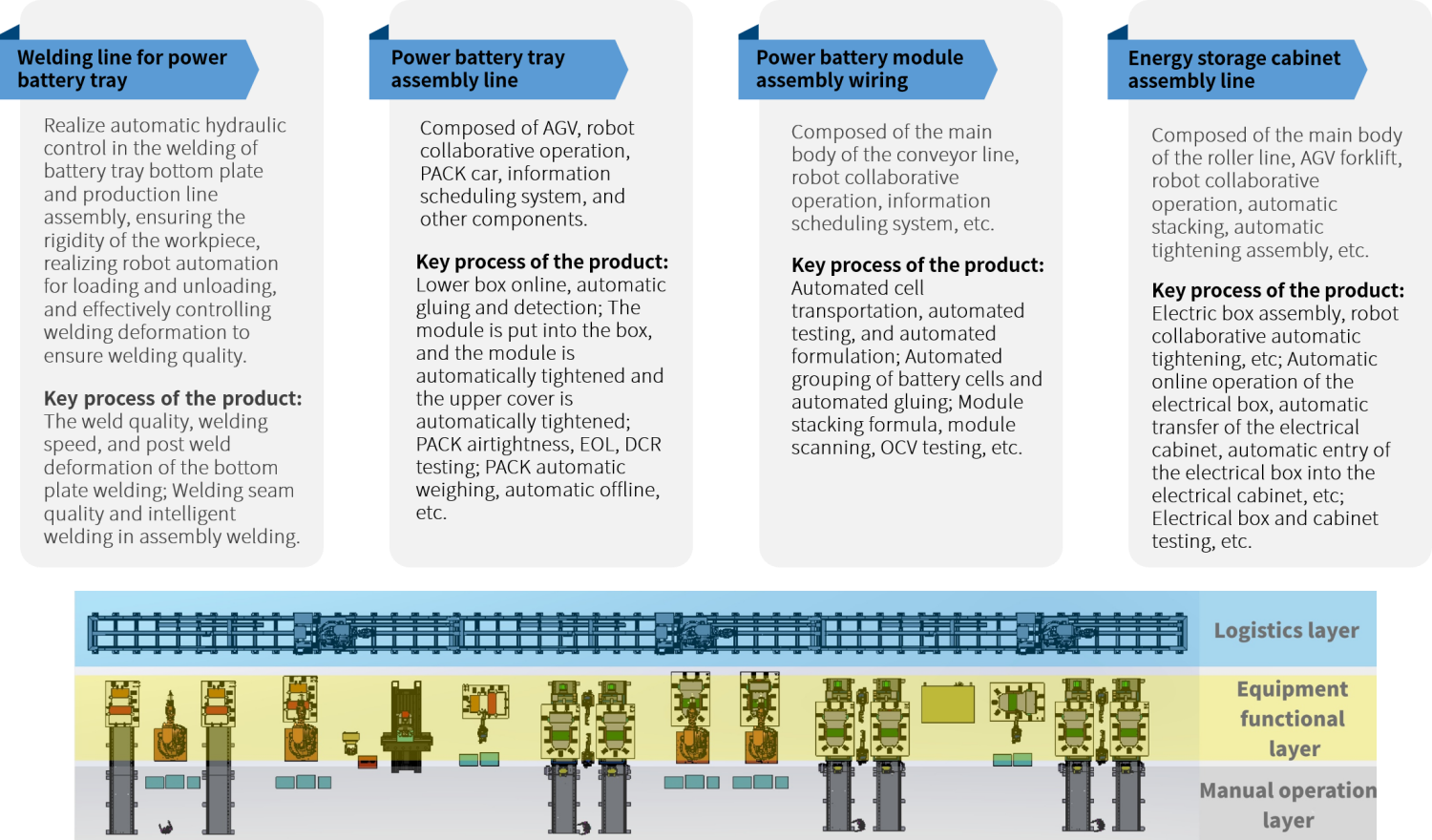

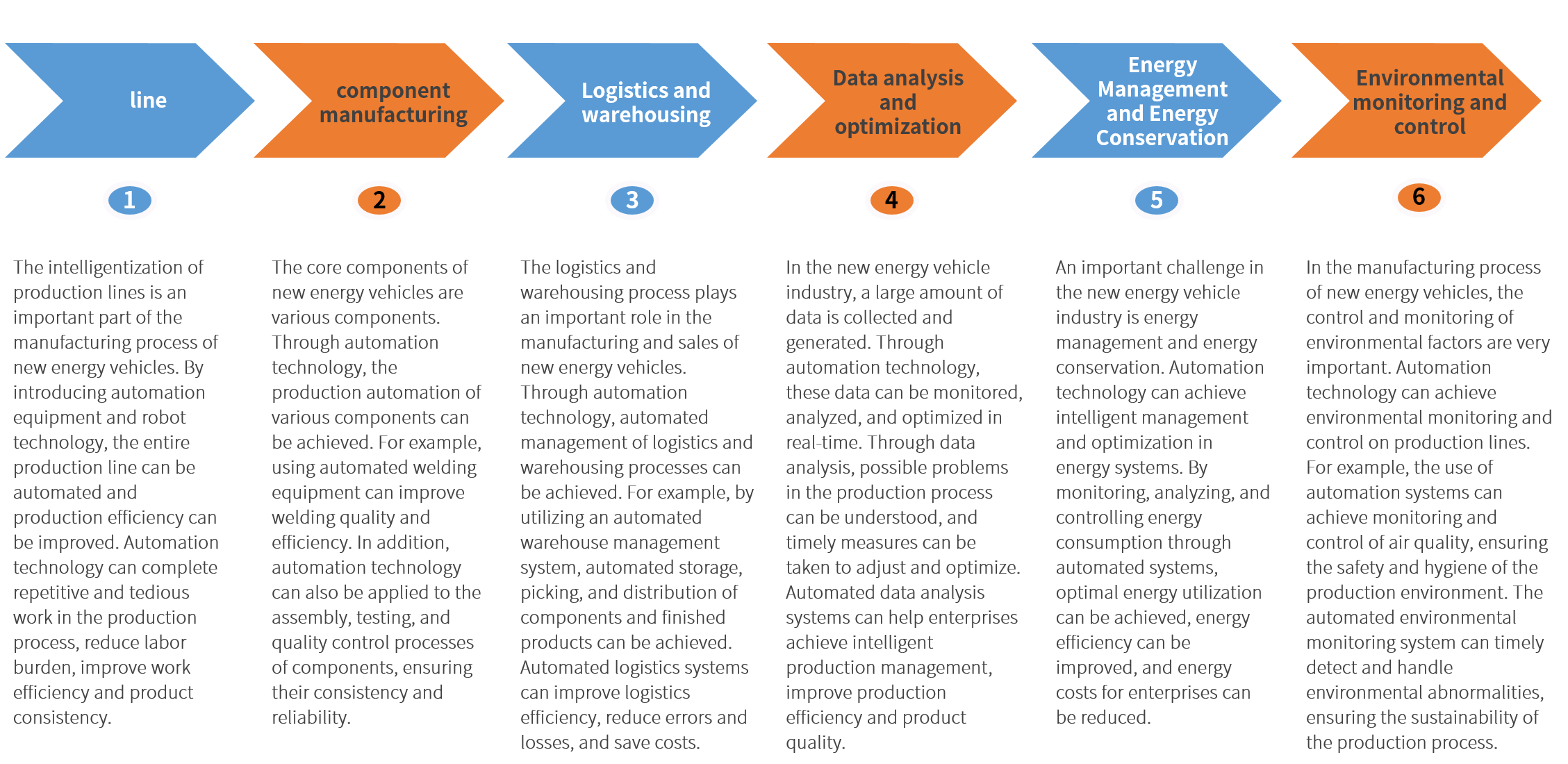

Solutions for the New Energy Vehicle Industry

Intelligent technology is widely applied in various industries and has had a huge impact on the new energy vehicle industry. Intelligent solutions can not only improve production efficiency and product quality, but also reduce costs, save energy and reduce emissions, enhance sustainable development capabilities, and further promote the development of the new energy vehicle industry. With the continuous innovation and development of intelligence and digital technology in the future, the new energy vehicle industry will usher in a broader development prospect.

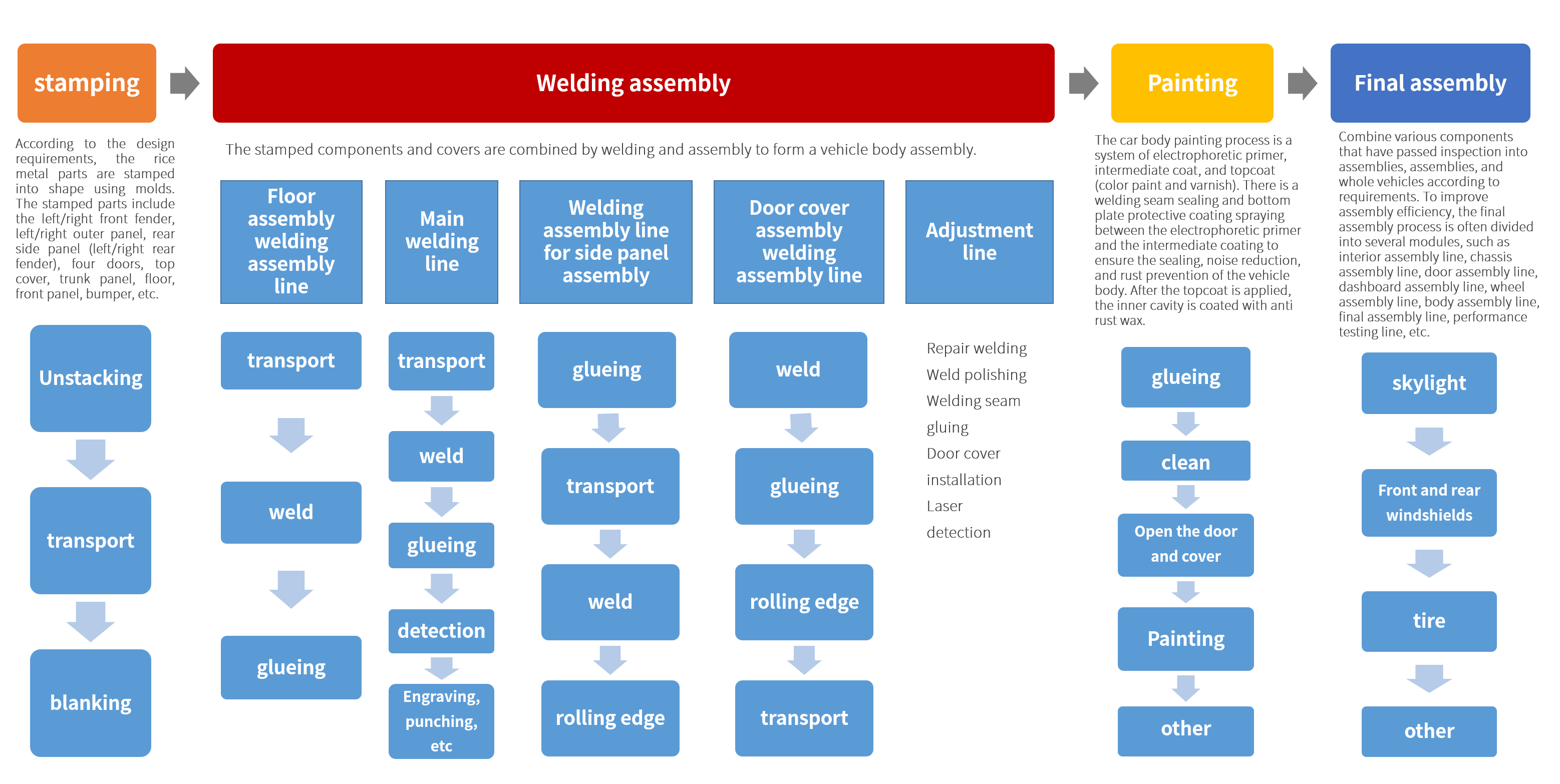

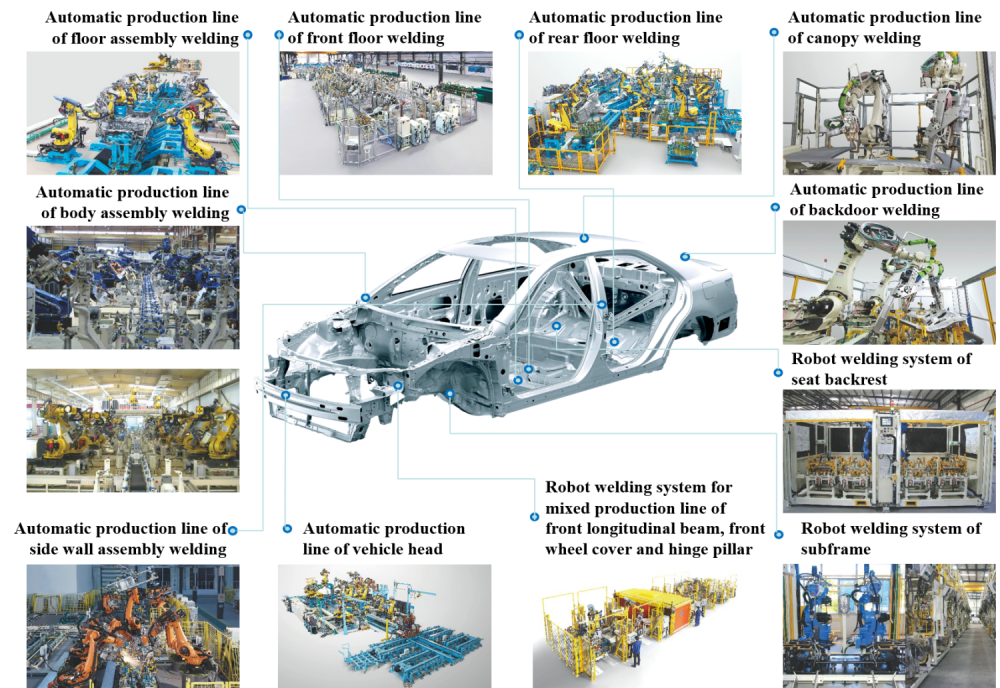

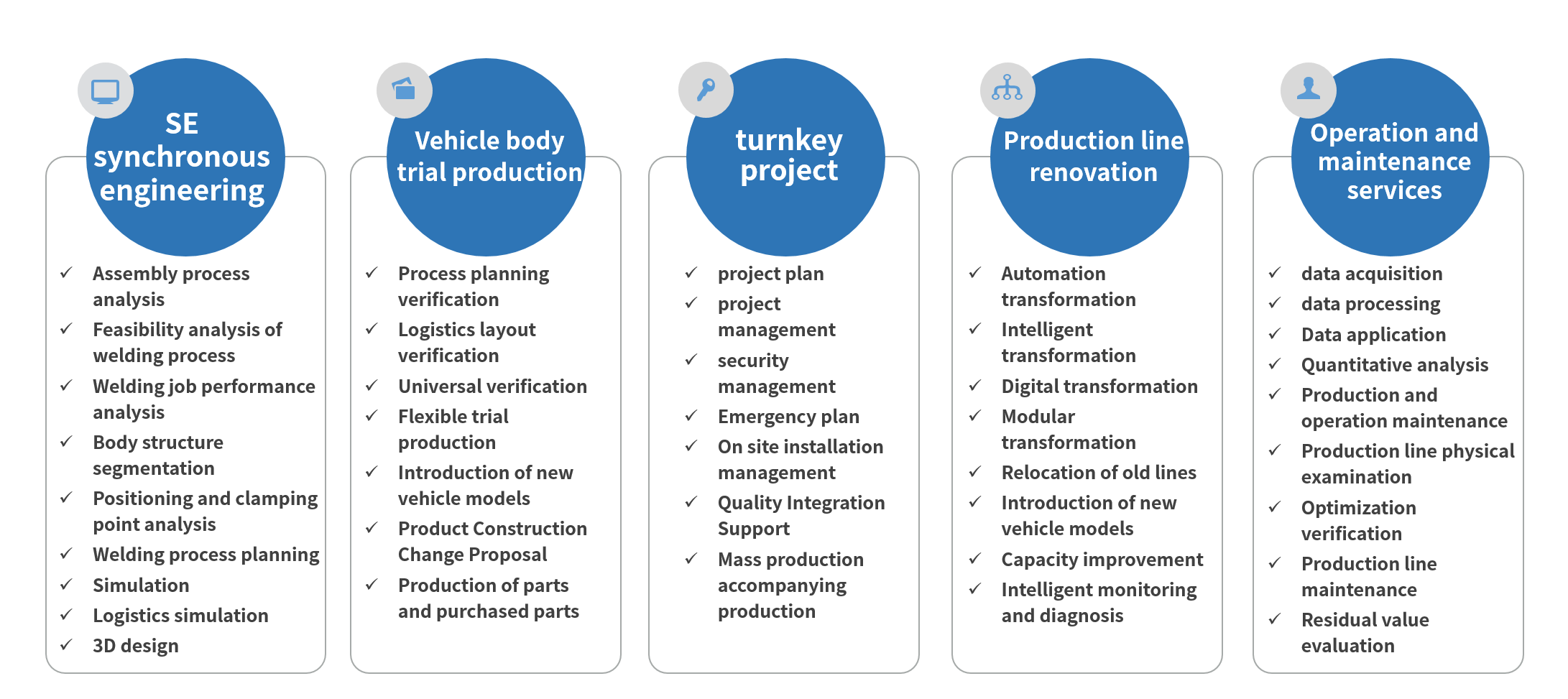

Intelligent solution for white body welding and assembly

The intelligent system solution for welding and assembly production lines of white body and body parts mainly covers synchronous engineering of body process planning, body trial production, turnkey engineering, production line renovation, operation and maintenance management, and services. The welding and assembly process of the white body mainly includes spot welding, arc welding, unilateral welding, screw welding, rotary tapping riveting, self piercing riveting, flexible rolling, gluing, laser welding, etc.

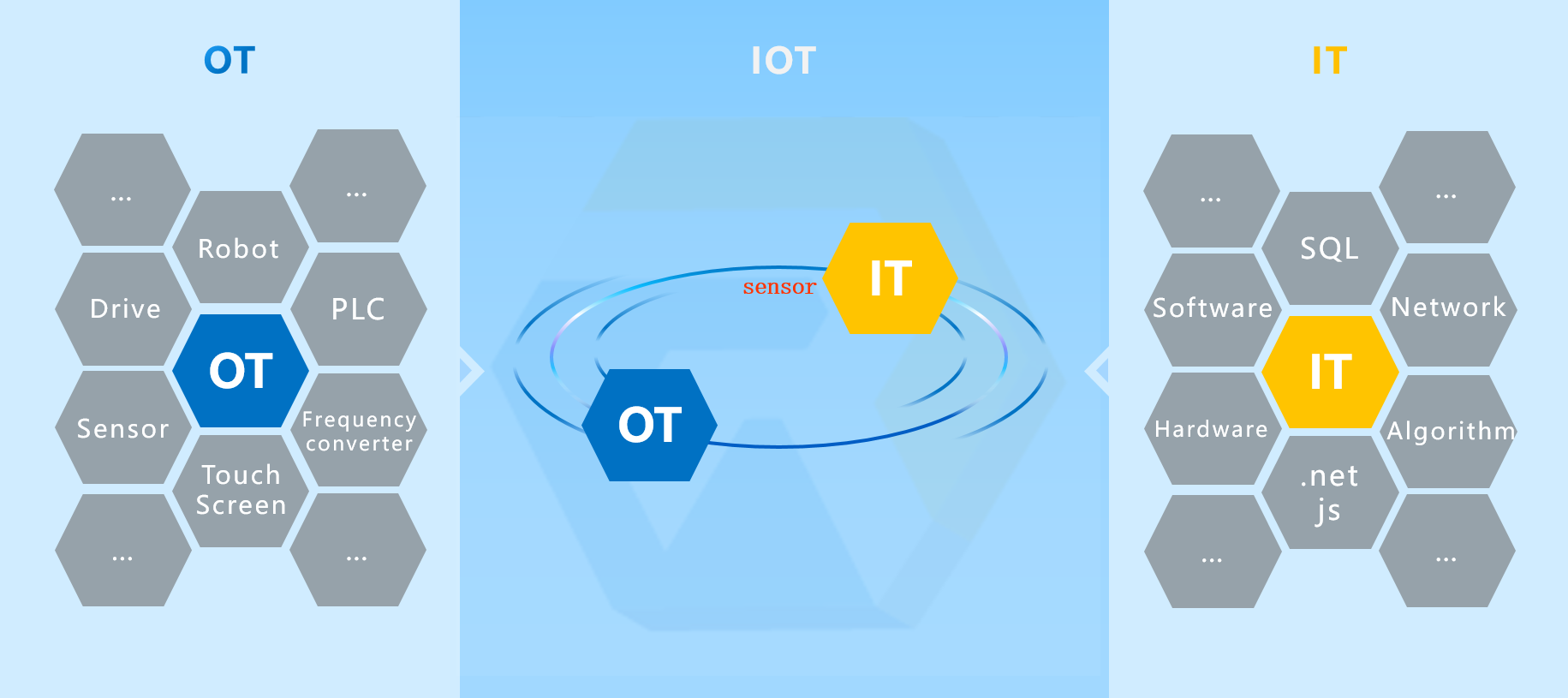

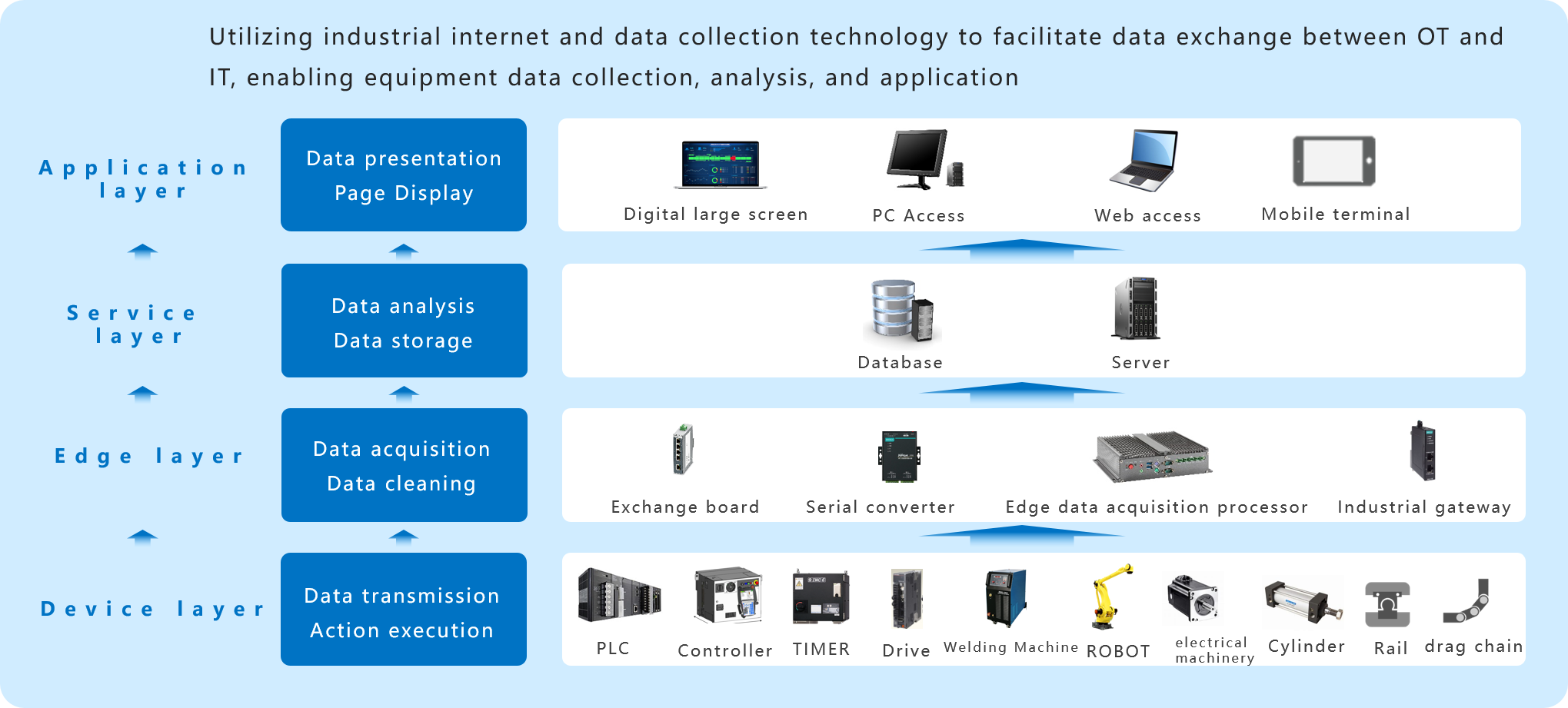

Digitalization and intelligentization of production lines

Risong Technology's digital platform RIDP is a core platform that closely links people, machines, and data. It includes a production line operation monitoring system, equipment operation and maintenance management system, equipment symptom management system, and welding quality management system. It integrates data systems such as production line, equipment operation and maintenance, equipment diagnosis, and welding monitoring, achieving visual, convenient, intuitive, and data-driven production management, and achieving refined management of production lines.